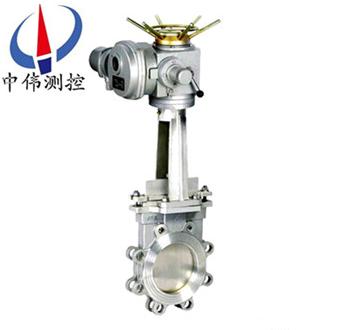

Electric quincunx type knife gate valve

Summary of one, the gate valve.

1, quincunx PZ973 series electric knife gate valve according to different made into non-rising stem and stem diameter two forms (non-rising stem (~ 900 mm, rising stem (~ 900 mm), all round the dc channel design of sludge, BuKa resistance.Knife plate bottom into the blade shape processing of soft materials such as fiber, paper pulp, wood pulp has cut off function, at the same time has good opening and closing action.In the upper blade equipped with hard teflon wiper, can prevent the dust and scratch sexual material such as gravel into the stuffing box, can significantly improve the blade life.The valve material selection of stainless steel, fine grinding and polishing treatment can obtain ideal sealing effect.Compact design, occupying small space, light weight, cheap, easy to install, wear-resisting prevent measures to perfect, easy maintenance, easy to use and long service life, and can choose which drives.

2, the valve body, stuffing box are precision casting, which the body USES the integral casting flange type, material can be selected according to user needs 304, 316, 316 l, WCB, 2 crl3, sealing ring using PTFE reinforced PTFE material, corrosion resistance, wear resistance, non-stick slag.

3, valve plate, there are five points, the valve plate has good from to.When the valve is closed, and back pressure, the valve plate is not skewed.

4, knife gate valves can be furnished with handwheel, manual zipper, is gear, bevel gear drive, pneumatic and electric.

Inside, knife gate valve can be made into 5 V, triangle, pentagon channel.V gate can be used as adjusting control.

6, knife gate valve connection has the wafer, flange type, sealed with a metal to metal hard seal, metal for polyurethane, with enhancement of ptfe soft seal.

7, suitable medium: gold ores, tailings, paper pulp, wood pulp, fiber, dust, chemical sewage, sedimentation tank, sand, slag, coal slurry, asphalt, bin exports, fruits, grain, cement, the abattoir wastewater, etc.

8, the working temperature: soft sealing (PTFE) : - 40 ℃ ~ 180 ℃;Carbon steel: - 29 ℃ ~ 425 ℃;Stainless steel: - 40 ℃ ~ 600 ℃;Molybdenum chrome vanadium steel: 550 ℃ or less;Job stress: 0.6 to 1.6 mpa.

Second, quincunx PZ973 series electric knife gate valve standards:

Designed according to JB/T869l - 1998 MSS - SP - 81;

The flange according to GB/T9113.1-2000.

Structure length according to GB/T1-5188.2-94;

Test and acceptance according to GB/T13927.

Three, the valve USES and features:

Quincunx PZ973 series electric knife gate valve is widely used in chemical industry, coal, sugar, sewage, paper, fly ash treatment, the use of material transportation, food and beverage industry requirements and working conditions are harsh environmental conditions inferior areas, is an ideal sealing valve.Type knife gate valve is particularly suitable for papermaking industry used on the pipeline to adjust and throttling.PZ973H type electric knife gate valve driving part adopts multi-turn electric device, is used to drive and control the opening and closing of the valve, operators can to control the valve in the control room distance can also be the scene manual operation, can also cooperate with computer to realize computer automatic control.

1, the structure of the wafer, small volume, light weight, small flow resistance, easy installation and maintenance.

2, completely open channel, can prevent the medium inside the valve deposits.

3, newly developed sealing ring, U can ensure good sealing of the valve.

4, outside of the gate seal, it is through the embedded in the body of elastic sealing strip, and with the aid of screw, clamp to adjust.

Four, electric device parameters and features:

parameter

1, power supply: AC380V, 50 hz.

2, standard: standard products with dust, prevent the rain shell, protective class IP65 protection ability, can be directly used in outdoor.

3, waterproof type: waterproof type products with dust, prevent flooding (IP67) shell protection grade.

4, explosion-proof type (EX) : explosion-proof grade for DII BT4 / DII CT4 (excluding acetylene).

5, environmental temperature: - 20 ℃ ~ 425 ℃.

6, optional: electrical controller.

Features:

1, the opening and closing fast, balanced and reliable, high degree of automation.

2, installation height and position is not restricted.

3, using explosion proof electric actuator, in flammable and explosive, even poisonous gas can work normally in the environment.

4, is equipped with manual, one thousand a continuous power supply can be manually open or close the valve, effectively control medium, prevent accidents.

Five type, electric knife gate valve technical parameters:

Nominal pressure (MPa) | Shell test (MPa) | Sealing test (MPa) | Working temperature | Applicable medium |

1.0 | 1.5 | 1.1 | 100 ℃ -- 425 ℃ or less | Pulp, waste water, coal slurry, slag, ash and water mixture |

Six, valve parts material:

Body and cover | ram | The valve stem | Sealing surface |

Stainless steel, carbon steel, gray cast iron | Stainless steel | Stainless steel | Rubber, ptfe, stainless steel, cemented carbide |

Seven,

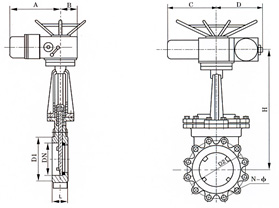

Main shapes and connection size (mm)

Nominal pressure | DN | L | D1 | D2 | H | A | B | C | D | N - Φ | Denso type |

0.6 MPa | 50 | 48 | 90 | 110 | 600 | 215 | 125 | 318 | 197 | 4-M12 | DZ10 |

65 | 48 | 110 | 130 | 670 | 215 | 125 | 318 | 197 | 4-M12 | DZ10 | |

80 | 51 | 125 | 150 | 680 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

100 | 51 | 145 | 170 | 700 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

125 | 57 | 175 | 200 | 720 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

150 | 57 | 200 | 225 | 790 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

200 | 70 | 255 | 280 | 850 | 215 | 125 | 363 | 197 | 8-M16 | DZ15 | |

250 | 70 | 310 | 335 | 1100 | 215 | 125 | 363 | 197 | 12-M16 | DZ20 | |

300 | 76 | 362 | 395 | 1180 | 215 | 125 | 363 | 197 | 12-M20 | DZ20 | |

350 | 76 | 412 | 445 | 1280 | 215 | 125 | 363 | 197 | 12-M20 | DZ30 | |

400 | 89 | 462 | 495 | 1460 | 215 | 125 | 363 | 197 | 16-M20 | DZ45 | |

450 | 89 | 518 | 550 | 1600 | 240 | 235 | 437 | 277 | 16-M20 | DZ45 | |

500 | 114 | 568 | 600 | 1800 | 240 | 235 | 437 | 277 | 16-M20 | DZ60 | |

600 | 114 | 670 | 705 | 2100 | 240 | 235 | 437 | 277 | 20-M22 | DZ60 | |

700 | 127 | 775 | 810 | 2300 | 274 | 260 | 526 | 283 | 24-M22 | DZ90 | |

800 | 127 | 880 | 920 | 2500 | 274 | 260 | 526 | 283 | 24-M27 | DZ120 | |

900 | 154 | 980 | 1020 | 2700 | 319 | 295 | 554 | 309 | 24-M27 | DZ180 | |

1000 | 165 | 1080 | 1120 | 2900 | 319 | 295 | 554 | 309 | 28-M27 | DZ250 | |

1200 | 190 | 1295 | 1340 | 2300 | 319 | 295 | 554 | 309 | 32-M27 | DZ250 | |

1.0 MPa | 50 | 48 | 100 | 125 | 600 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 |

65 | 48 | 120 | 145 | 670 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

80 | 51 | 135 | 160 | 680 | 215 | 125 | 318 | 197 | 4-M16 | DZ10 | |

100 | 51 | 155 | 180 | 700 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

125 | 57 | 185 | 210 | 720 | 215 | 125 | 318 | 197 | 8-M16 | DZ10 | |

150 | 57 | 210 | 2400 | 790 | 215 | 125 | 363 | 197 | 8-M20 | DZ15 | |

200 | 70 | 265 | 295 | 850 | 215 | 125 | 363 | 197 | 8-M20 | DZ20 | |

250 | 70 | 320 | 350 | 1140 | 215 | 125 | 363 | 197 | 12-M20 | DZ20 | |

300 | 76 | 368 | 400 | 1180 | 215 | 125 | 363 | 197 | 12-M20 | DZ30 | |

350 | 76 | 428 | 460 | 1280 | 215 | 125 | 363 | 197 | 16-M20 | DZ30 | |

400 | 89 | 482 | 515 | 1460 | 240 | 235 | 437 | 277 | 16-M22 | DZ45 | |

450 | 89 | 532 | 565 | 1600 | 240 | 235 | 437 | 277 | 20-M22 | DZ45 | |

500 | 114 | 585 | 620 | 1800 | 240 | 235 | 437 | 277 | 20-M22 | DZ60 | |

600 | 114 | 685 | 725 | 2100 | 240 | 235 | 437 | 277 | 20-M27 | DZ60 | |

700 | 127 | 800 | 840 | 2300 | 274 | 260 | 526 | 238 | 24-M27 | DZ120 | |

800 | 127 | 898 | 950 | 2, 500, | 319 | 295 | 554 | 309 | 24-M30 | DZ180 | |

900 | 154 | 1005 | 1050 | 2700 | 319 | 295 | 554 | 309 | 28-M30 | DZ180 | |

1000 | 165 | 1115 | 1160 | 2900 | 319 | 295 | 554 | 309 | 28-M30 | DZ250 | |

1200 | 190 | 1325 | 1380 | 3400 | 319 | 295 | 554 | 309 | 32-M36 | DZ258 |

Eight, ordering information:

1, please understand this product carefully before order - type knife gate valve, clearly indicate the type, model, material quality, pressure and quantity.

2, it is very important when using occasions or when the environment is more complex, please try to provide the design drawings and detailed parameters, by wei measurement experts in our audit checks for you.

3, when ordering type knife gate valve, please fill in detail the order unit, the receiving unit, the unit of payment, the name of the mailing address (including province, city, ground, district, street, number), phone, bank, account and representative.

4, order, all our products are for cash or your shipment to pick up the goods.

Nine, inspection (discharge) guidelines:

1, carefully controlled and when ordering products (type knife gate valve), and packing if there is any breakage, etc.

2, choose suitable methods and tools, to prevent deformation or damage to the product;My company pays attention to service problems, in order to achieve customer satisfaction product standards we must shoulder to shoulder with customers to share their experiences, information and commitment, the goal, to cooperative relations to develop good products.No matter you ask product design principle, price, technology, schedule, any problem such as transport routes, has a specific customer service staff to answer you.